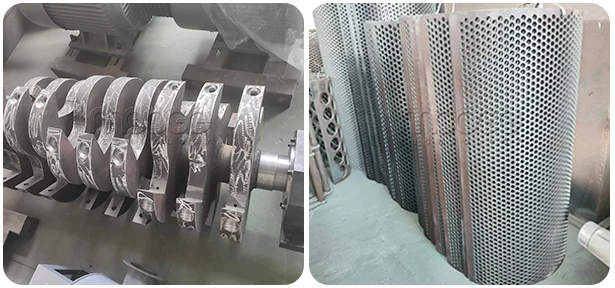

Function: crushing the material into flakes

>With water inlet can do wet crushing

>Use big roller bearing ensure durable use

>With heavy duty pulley easier for machine working

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

> Upside hopper is covered by shelter so no flakes popped out.

>Bearing house is installed outside of the chamber so no dirty goes inside which prolong the lifespan

> Upside hopper is covered by shelter so no flakes popped out.

English

English